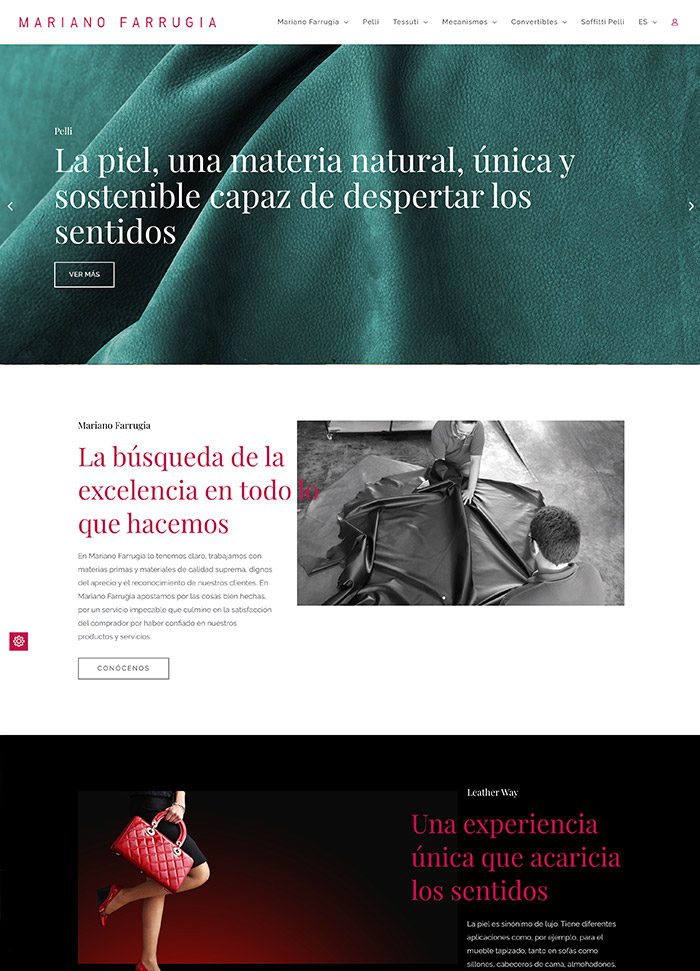

Mariano Farrugia

Empresa fabricante de productos de piel

En Mariano Farrugia lo tenemos claro, trabajamos con materias primas y materiales de calidad suprema, dignos del aprecio y el reconocimiento de nuestros clientes. En Mariano Farrugia apostamos por las cosas bien hechas, por un servicio impecable que culmine en la satisfacción del comprador por haber confiado en nuestros productos y servicios.

Leather Way

Especialistas en Fabricación de Pieles

La piel es sinónimo de lujo. Tiene diferentes aplicaciones como, por ejemplo, para el mueble tapizado, tanto en sofás como sillones, cabeceros de cama, almohadones, alfombras, asientos de automóviles, revestimientos de paredes y techos, marroquinería, calzado…, dando como resultado, en cada caso, piezas únicas e irrepetibles. Cada piel tiene una historia diferente. Sus marcas o sus huellas son el testimonio evidente de esa experiencia.

La elaboración de la piel es una de las artes más antiguas que acompaña al hombre desde sus orígenes. La piel es un material duradero, versátil y natural. Es un producto de gran valor, buscado para una amplia gama de usos diferentes. Leer más

La piel es una materia natural, única y sostenible, capaz de despertar los sentidos. Una vez concluido el proceso de curtición y fabricación de la misma, y antes de ser enviada al cliente, pasa una serie de controles de calidad que corroboran que ésta cumple con las principales normativas de calidad exigidas, garantizando así los parámetros de durabilidad determinados para la piel, siempre y cuando sea tratada de manera correcta y con los productos adecuados. El secreto para una piel perfecta pasa por su cuidado y su limpieza. Leer más.

Se trata de una web con un aspecto más moderno y más organizado, que representa mejor a Mariano Farrugia.

Una de las principales diferencias o cambios que incorpora este nuevo espacio web es que ya no solamente mostramos la piel sino… Leer más.

Soffitti Pelli. Fabricación de Piel a tu medida.

Soffitti es la piel de la arquitectura, el tacto del espacio interior. Muros y techos revestidos en piel que acarician los sentidos. Soffitti es icono de modernidad basado en la inspiración clásica. La variedad de sus placas y sus posibilidades compositivas dan como resultado un proyecto de interiorismo diferente y exclusivo. Soffitti convierte el espacio en una estancia única, que despierta el deseo de ser habitada. ¡Soffitti es tu segunda piel!

Programa de ayuda: Préstamos dirigidos a proyectos de inversión. Línea de préstamos para el crecimiento empresarial. Este programa ha sido cofinanciado por el Fondo Europeo de Desarrollo Regional y el Instituto de Fomento de la Región de Murcia.

Nº Expediente: 2023.07.LPCE.000061

Hemos participado en la MISIÓN COMERCIAL DIRECTA CONTRACT A PERÚ Y COLOMBIA, 2-8 JULIO 2023, organizada por el Instituto de Fomento de la Región de Murcia y cofinanciada por el Fondo Europeo de Desarrollo Regional (FEDER) y el Instituto de Fomento de la Región de Murcia.